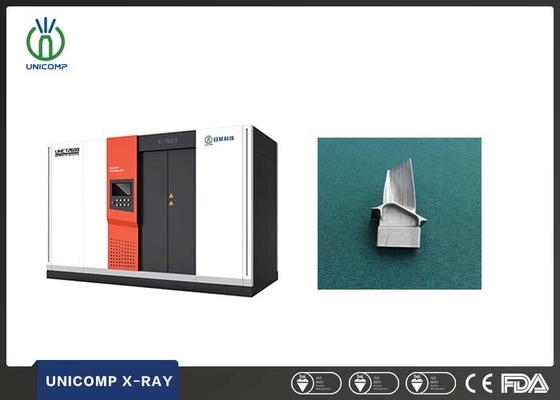

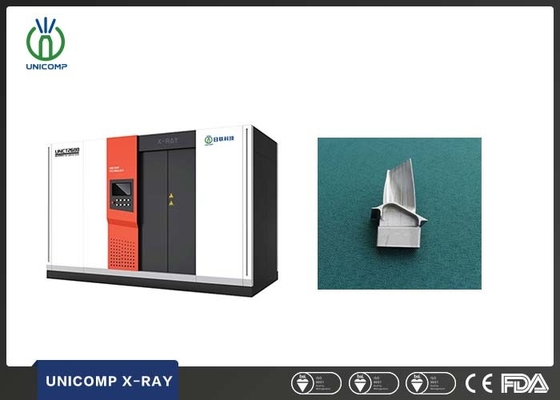

High accuracy porosity X-ray computed tomography machine Unicomp UNCT2600 for engine blades 3D CT inspection

Product Description:

The UNCT2600 is a compact and versatile industrial CT scanning system renowned for its high precision, catering to the diverse inspection needs across various industries. Predominantly utilized for examining small metal castings, non-ferrous metals, lithium-ion battery cells, microchips, electronic components, geological rock samples, cores, soil samples, fossils, composite materials, biological specimens, and a myriad of other detection applications.

Features:

- Functions: It seamlessly integrates the dual imaging detection capabilities of DR and CT, facilitating advanced 3D scanning, exhaustive data reconstruction, and in-depth analysis.

- Safety: It guarantees an unparalleled level of safety, ensuring that radiation exposure remains well within the national safety thresholds, while also incorporating multiple robust safety measures for added protection.

- Operation: Designed with a user-focused control system, it streamlines operation, enabling operators to effortlessly master its functionality with minimal training.

- Precision: It showcases a high-precision mechanical transmission system, paired with cutting-edge image processing and analysis software, resulting in unparalleled detection accuracy.

Technical Parameters:

| Product Name: | High accuracy porosity X-ray computed tomography machine Unicomp UNCT2600 for engine blades 3D CT inspection |

| Dimensions: | 3550mm*1750mm*2400mm(L*W*H) |

| Machine Weight: | 7000kg |

| Pixel Matrix: | 3072*3072 |

| Pixel Size: | 139μm |

| Voltage: | 225KV |

| X-ray tube type | Split tube |

| Training: | Yes, we warmly welcome you to visit our factory, we will arrange the free training for you. |

| Services: | Help customers analyze product projects and provide detection solutions. Free sample detection test. Provide professional detection solutions. We have skilled jig design services. Provide shipping/delivery information checking service. One year guarantee, all life maintain promise. 24-hour feedback speed by email to others. |

Applications:

The Industrial X Ray Machine product can be used across a variety of industries and applications. Here are some of the occasions and scenarios where the product can be used:

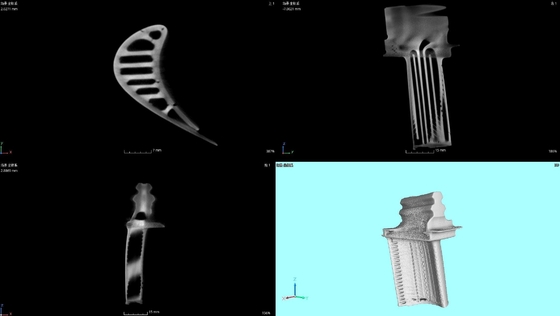

- Defect Detection: Industrial CT precisely identifies internal flaws like cracks, voids, and inclusions without damaging the sample, ensuring product quality.

- Wall Thickness Analysis: Accurately measures wall thickness variations and gaps, enabling fine-tuning of complex components.

- CAD Comparison: Validates CAD designs by comparing them with actual part geometries, uncovering discrepancies and facilitating design optimization.

- Metrology/Coordinate Measuring: Provides high-accuracy dimensional measurements, complementing traditional coordinate measuring machines (CMMs) for comprehensive quality control.

- Fiber Composite Analysis: Uncovers defects like delamination, porosity, and resin cracks in composites, enhancing material reliability and durability.

- Transfer Phenomena: Enables visualization of fluid flow, heat transfer, and other phenomena within materials and structures, aiding in design optimization.

- Structural Mechanics Simulation: Coupled with simulation tools, predicts stress, deformation, and failure modes, informing stronger, lighter designs.

- Reverse Engineering: Converts existing parts into precise CAD models, facilitating replication, redesign, and reverse-engineering processes.

Support and Services:

Our Industrial X Ray Machine product comes with comprehensive technical support and services to ensure optimal performance and reliability. Our trained technicians are available to provide assistance with installation, setup, and calibration of the machine. In addition, we offer ongoing maintenance and repair services to keep the machine running smoothly and to minimize downtime. Our team also provides training and consultation services to help users get the most out of the machine and to ensure safe and effective operation. Contact us for more information about our technical support and services.

FAQ:

Q: How about the package? Is it safe during the delivery?

A: All X-ray inspection machine is packed with standard wooden solid carton. It is safe when shipping.

Q: Do you provide the Warranty? How about the after-sales service?

A: 1-year warranty free for spare parts, Whole life technical support.

We have a professional after-sales team, if any questions, assistant videos are also provided in the after-sale service.

Q: If we come to your factory if you will provide free training?

A: Yes, we warmly welcome you to visit our factory, we will arrange the free training for you.

Inspection Images:

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!